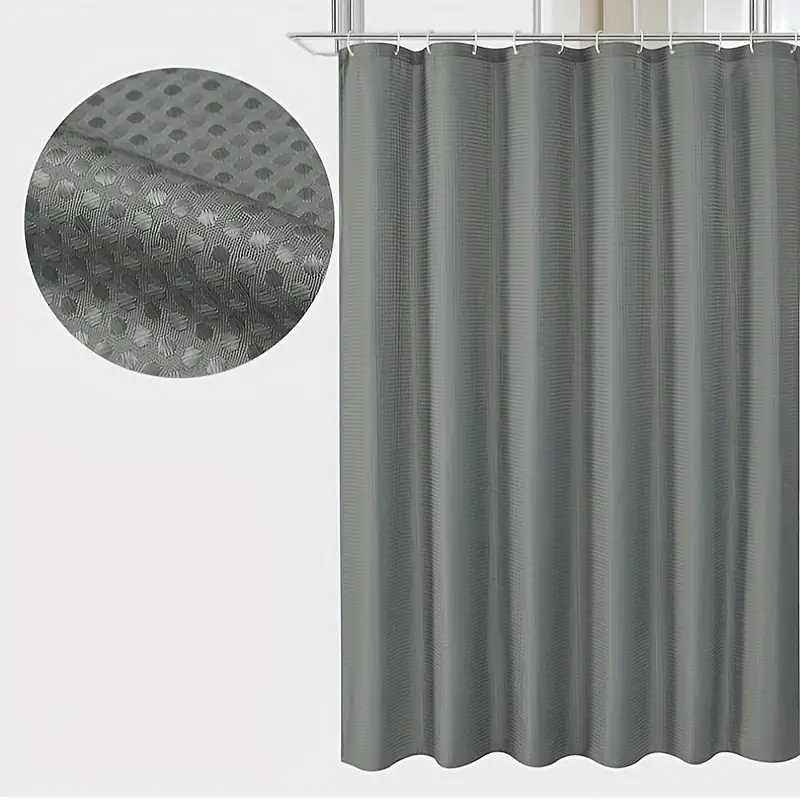

MitoVilla Salbeigrüner Waffelstoff Duschvorhang, schwere Stoff-Duschvorhänge für moderne Hotel-Badezimmer-Dekoration, langlebig und knitterfrei, 183 x 183 cm : Amazon.de: Küche, Haushalt & Wohnen

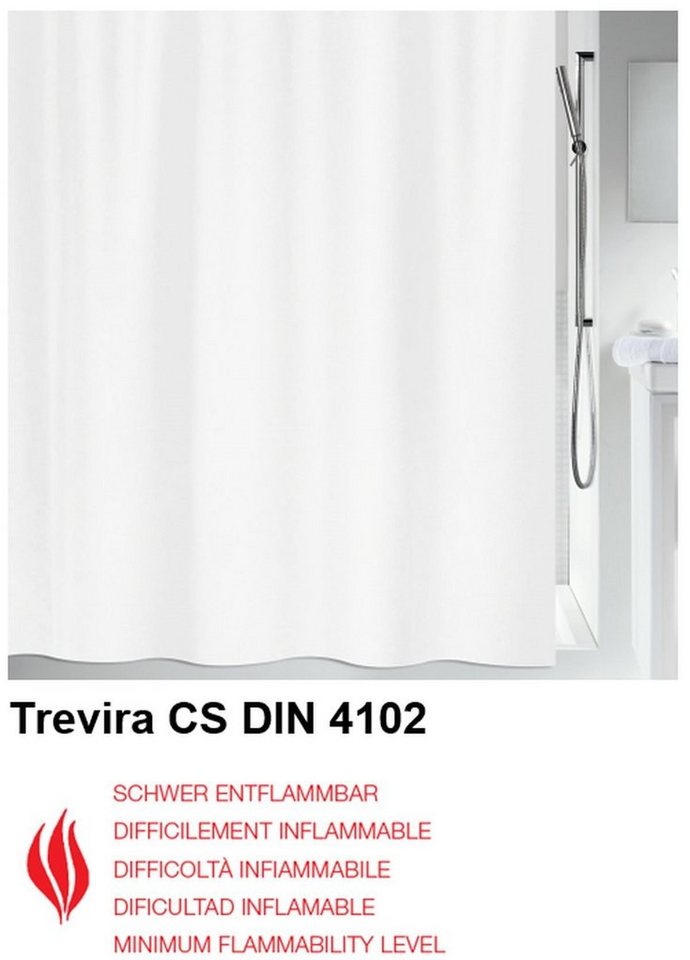

spirella Duschvorhang SECURITAS Breite 120 cm, Premium Textil-Duschvorhang, 100% Polyester, schwer entflammbar Trevira© CS DIN 4102 Brandschutznorm B1, Made in Europe, wasserabweisend, Anti-Schimmel-Effekt, waschbar 40°, Farbe weiß, Größe 120 x 200 cm

Hiseng Duschvorhang Schwer mit Gewicht Saum, Wasserdicht Polyestergewebe Duschvorhänge, Pflanze Muster Duschvorhänge Waschbar Badevorhang mit 12 Haken, Badewannendekor (150x180cm,Aquarell Blätter) : Amazon.de: Küche, Haushalt & Wohnen

M&W DAS DESIGN Duschvorhang aus schwerem Textil Gewebe Leinenoptik schwere Qualität Schimmelresistent Stoff Luxus 100% Wasserdicht Blickdicht inkl. 12 Haken Gewicht unten 180x200cm(BxH) grau : Amazon.de: Küche, Haushalt & Wohnen

spirella Duschvorhang TRENTO Breite 180 cm, Anti-Schimmel Textil- Duschvorhang, schwere Qualität Baumwolle / Polyester, mit erhabener Stickerei, 180x200 cm, waschbar, Made in Europe

WOLTU Duschvorhang Wasserdicht Anti-schimmel, Waschbar Shower Curtains, Schwerer Badvorhang aus Polyester Stoff, Badewanne Vorhang mit Duschvorhängeringen,120 x 180 cm, weiß

MSV Duschvorhang NATUREL, Anti-Schimmel Textil-Duschvorhang, schwere Qualität Baumwolle/Polyester, wasserabweisend, Anti-Schimmel, Anti-Bakteriell, waschbar, Made in Spain, 180x200, beige-natur